Table of Contents

ToggleQuality Assurance in Modern Wood Door Production

In the intricate world of modern wood door production, understanding how to ensure quality is paramount. From selecting high-quality wood materials to executing advanced manufacturing techniques, every step plays a crucial role in crafting doors that meet the highest durability and aesthetic appeal standards. My extensive experience has taught me that recognising the unique qualities of timber types and integrating sustainable practices can significantly enhance the production process.

Precision cutting tools and rigorous quality assurance testing are essential in maintaining consistency and excellence in door manufacturing. By leveraging advanced technology and fostering skilled craftsmanship, wood door manufacturers can balance efficiency and quality. This article delves into the nuances of modern wood door production, offering insights into sourcing sustainable wood, maintaining consistent moisture control, and applying durable finishing techniques to ensure that every door produced is a testament to superior quality and environmental responsibility.

Picking High-Quality Wood Materials for Modern Wood Door Production

In modern wood door production, the structure of high quality begins with the careful selection of wood products. The selection of wood directly affects the resilience, aesthetic appeal, and overall efficiency of the final product. With my considerable experience, I have found that recognizing the unique qualities of various wood types is important for ensuring the production of high-quality doors.

Recognizing Wood Types

Different wood species supply one-of-a-kind buildings that impact their viability for door manufacturing. Here are some crucial kinds frequently used in the market:

| Wood Type | Features | Applications |

|---|---|---|

| Oak | Solid, durable, and aesthetically pleasing with a prominent grain pattern. | Premium exterior and interior doors. |

| Maple | Tough and dense with a penalty, consistent texture. | Interior doors need a smooth finish. |

| Mahogany | Resistant to rot and insects, with a rich, reddish-brown colour. | Costs outside doors. |

| Pine | Lightweight and simple to collaborate with, yet much less resilient than hardwoods. | Cost-effective indoor doors. |

Reviewing Wood Quality

To guarantee the best quality in modern wood door production, it is necessary to examine the quality of the timber before use. Secret variables to think about include:

- Moisture Content: The timber needs to be correctly experienced and have a dampness material of around 6-8% to avoid bending and cracking.

- Grain Pattern: Consistent and straight grain patterns are liked for their visual allure and architectural stability.

- Knots and Defects: Minimize the presence of knots and flaws, as they can weaken the door and impact its look.

Sourcing Sustainable Wood for Modern Wood Door Production

Including sustainable techniques in wood sourcing is significantly vital in modern wood door production. Going with wood from properly managed woodlands not only sustains ecological preservation but also ensures a trustworthy supply of high-quality products. Search for qualifications such as the Forest Stewardship Council (FSC) to verify the sustainability of your timber resources.

By prioritizing the option of high-quality wood materials, suppliers can lay a strong foundation for creating doors that fulfil the needs of modern consumers in terms of both performance and design.

Executing Advanced Modern Wood Door Production Techniques

In the realm of modern wood door production, the adoption of sophisticated manufacturing techniques stands as a foundation for guaranteeing extraordinary high quality. These strategies not only enhance the performance of production procedures but also dramatically boost the accuracy and durability of the end product.

Automation and Robotics

The combination of automation and robotics in making procedures has reinvented the manufacturing of wood doors. Automated systems permit constant and exact procedures, minimizing human error and making sure of harmony throughout sets. Robotics can handle repeated tasks effortlessly, freeing competent craftsmen to focus on even more elaborate information that requires human touch.

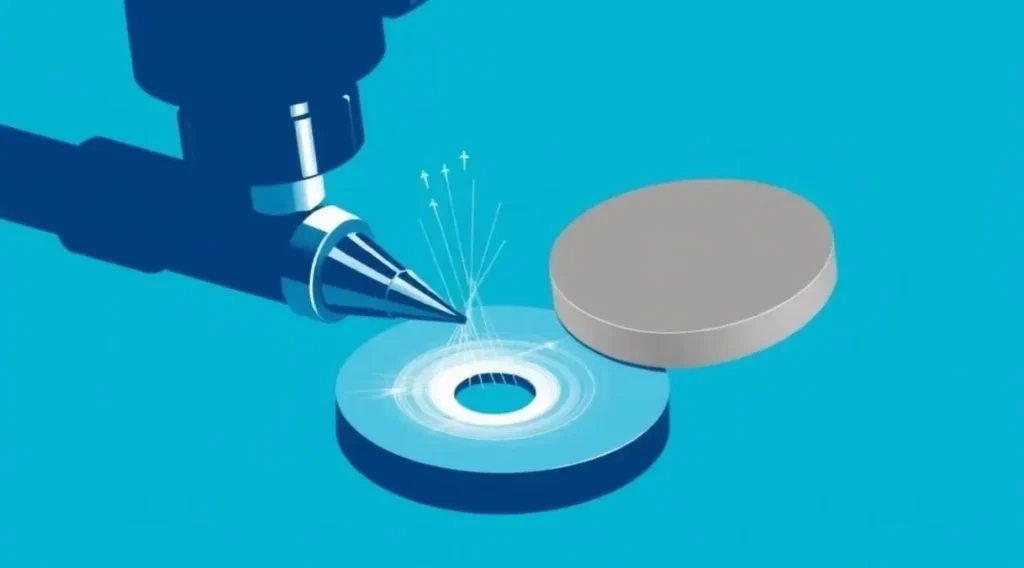

Computer System Numerical Control (CNC) Machines

Using Computer Numerical Control (CNC) equipment is essential in accomplishing accurate cutting and shaping of wood elements. These equipment are programmed to execute complicated designs with high precision, making certain that each item fits flawlessly in the assembly process. CNC technology also permits quick prototyping, making it possible for manufacturers to evaluate and improve designs effectively.

Lean Manufacturing Principles

Implementing lean manufacturing principles is crucial in maximizing manufacturing processes. By minimizing waste and making the most of source use, producers can boost efficiency while preserving high-quality standards. Lean techniques motivate continual improvement, fostering a setting where top quality is a constant focus.

Advanced Quality Control Systems for Modern Wood Door Production

Advanced quality assurance systems are essential to maintaining high requirements in modern wood door production. These systems utilize sensors and software applications to keep an eye on and assess numerous specifications throughout the production process. Real-time data collection enables immediate changes, guaranteeing that each item meets the defined quality requirements.

By accepting these innovative production methods, timber door manufacturers can attain an equilibrium between performance and quality, satisfying the needs of discerning customers while preserving affordable benefits.

Using Precision Cutting and Shaping Tools for Modern Wood Door Production

In the realm of modern wood door production, the use of accurate cutting and shaping devices is vital to ensuring top quality. These devices enable the creation of doors that are not just cosmetically pleasing but also structurally sound and sturdy. The integration of innovative innovation in these devices has reinvented the way we approach door production, using unrivalled accuracy and performance.

Relevance of Precision Tools

Precision tools are vital in achieving the exact dimensions and detailed layouts needed in today’s door manufacturing. The exact nature of these devices decreases material waste and ensures that each door satisfies strict top-quality standards. This precision is crucial in preserving the stability of the door’s layout and features.

| Device Type | Feature | Benefits |

|---|---|---|

| CNC Machines | Computer-controlled cutting and shaping | High accuracy, repeatability, and effectiveness |

| Laser Cutters | Accuracy reduction for intricate designs | Clean cuts, marginal product wastefulness |

| Routers | Forming and describing edges | Versatility and precision inside the finish |

Combination of Technology

The integration of technology such as computer system mathematical control (CNC) makers and laser cutters has made it possible for producers to attain a level of precision that was formerly unattainable. These modern technologies permit the automation of complex cutting and forming jobs, reducing the probability of human error and raising the production rate.

Benefits of Precision Cutting and Shaping

Utilizing precision devices in modern wood door production offers several benefits:

- Consistency: Ensures each door generated equals high quality and look.

- Performance: Reduces production time and product wastage.

- Versatility: Allows for customization and complex layouts.

By leveraging these sophisticated tools, makers can keep high standards for indoor production, eventually providing products that meet the assumptions of both industry requirements and consumer fulfilment.

Ensuring Consistent Moisture Control

In modern wood door production, consistent moisture control is an important element that dramatically affects the high quality and durability of the end product. Keeping the appropriate dampness degrees in timber not only helps protect its structural integrity but also prevents common issues such as bending, breaking, and swelling.

Understanding Wood Moisture Content

Wood is a hygroscopic material, meaning it soaks up and releases wetness based on the surrounding environment. The wetness web content of timber is generally gauged as a portion of its weight. For modern wood door production, it is important to maintain wood moisture web content within a certain range, normally between 6% and 8%, to ensure stability and efficiency.

Dampness Control Techniques

Numerous strategies can be employed to achieve constant wetness control in timber. One efficient method is kiln drying, which includes making use of regulated warmth to minimize the wetness content to the desired level. This procedure not only maintains the wood but also boosts its workability and resistance to decay.

Another technique is the usage of moisture meters to consistently monitor the moisture levels in timber. These gadgets give precise analyses, allowing for timely changes to the manufacturing procedure if necessary. By ensuring that timber goes to the ideal wetness level before and throughout manufacturing, producers can avoid future concerns that could jeopardize the quality of the doors.

Ecological Controls

Maintaining a regulated environment in the production centre is essential. This includes controlling temperature and humidity degrees to stop changes that could affect the wood’s damp material. Modern wood door production often incorporates climate-controlled storage space and manufacturing locations to preserve consistency and top quality throughout the manufacturing procedure.

Benefits of Consistent Moisture Control

By prioritizing constant wetness control, suppliers can ensure that the timber doors generated are not just visually pleasing but also structurally sound and resilient. This focus on information in modern wood door production contributes dramatically to consumer contentment and the overall reputation of the manufacturing brand name.

Using Durable Finishing Techniques for Modern Wood Door Production

In the realm of modern wood door manufacturing, the application of resilient finishing strategies is important to ensure the long life and visual charm of the end product. This stage not only enhances the look of the wood but also gives necessary defence against environmental variables. A well-applied surface can substantially extend the lifespan of a wood door, making it a vital action in the production procedure.

Comprehending the Types of Finishes

Selecting the best finish is vital. Finishes can be categorized into several kinds, each offering one-of-a-kind benefits:

| Type of Finish | Attributes | Application |

|---|---|---|

| Oil-Based Finishes | Deep penetration, rich colour improvement | Brushed or sprayed |

| Water-Based Finishes | Quick drying, reduced smell, and environment-friendly | Cleaned or splashed |

| Polyurethane Finishes | High resilience, immune to chemicals and scrapes | Brushed or rolled |

| Varnishes | Glossy surface, UV security | Cleaned or sprayed |

Preparation and Application Techniques

Appropriate prep work on the wood surface is vital for accomplishing a top-quality surface. The surface area must be smooth, tidy, and free of any dust or particles. Fining sand is an important action in this process, as it enables the finish to adhere efficiently to the wood. Depending upon the kind of wood and wanted coating, various grits of sandpaper may be made use of.

Once the surface is prepared, the application technique will greatly rely on the sort of surface picked. It is very important to apply the coating uniformly to stop touches and make sure of a consistent look. Multiple coats might be needed, with sufficient drying time between each application to attain the desired sturdiness and look.

Guaranteeing Long-Lasting Protection

To ensure the coating supplies lasting defence, it is essential to think about ecological aspects such as humidity and temperature during application. Additionally, normal maintenance, such as cleaning and reapplication of the coating as needed, will aid preserve the door’s appearance and stability in time.

By implementing these durable finishing strategies, modern wood door production can achieve an item that not only satisfies visual criteria but also stands up to the examination of time.

Conducting Rigorous Quality Assurance Testing

In the realm of contemporary timber door manufacturing, conducting strenuous quality control testing is extremely important to ensure that each product fulfils the highest possible criteria of quality. This procedure entails numerous vital actions that are made to recognize and correct any type of potential concerns before the doors reach the consumer.

Visual Inspection

The initial step in quality assurance is a thorough visual inspection. This entails checking out each door for noticeable problems such as fractures, knots, or variances in the timber grain. It is important to catch these imperfections early in the production procedure to stop them from impacting the final product. An eager eye for detail is vital in this stage to maintain the aesthetic high quality of the doors.

Dimensional Accuracy

Making sure that each door meets the defined dimensions is anotherl critical part of quality control. This entails making use of accuracy measuring tools to verify that the doors adapt to the called-for elevation, width, and thickness. Any type of discrepancy from the specified dimensions can result in useful concerns or client dissatisfaction. Keeping dimensional accuracy is important for the smooth installation and operation of the doors.

Architectural Integrity Testing

Evaluating the structural integrity of the doors is vital to ensure they can withstand everyday usage. This involves applying pressure and tension examinations to replicate real-world conditions. By doing so, producers can recognize any weak points or vulnerabilities in the door’s building and construction. Making sure architectural integrity is critical to the longevity and durability of the product.

Dampness Content Analysis

Controlling moisture content is essential in protecting against bending and other moisture-related issues. During quality control testing, the dampness degrees in the wood are very carefully kept track of utilizing specific tools. Making sure that the wood goes to the ideal moisture degree aids in maintaining the door’s stability and prevents future issues.

Finishing Quality Assessment

The last action in the top quality guarantee process is evaluating the finishing high quality. This includes taking a look at the application of paints, discolourations, and sealants to ensure also insurance coverage and adherence. A high-quality surface not only improves the door’s look but also supplies crucial security versus ecological factors. Ensuring a resilient and visually pleasing surface is an essential facet of modern-day wood door production.

Integrating Sustainable Wood Door Production Practices

In modern wood door production, including lasting techniques is necessary to ensure both ecological obligation and high quality. As we aim to produce high-grade wood doors, it is critical to adopt approaches that minimize environmental influence while preserving the stability of our items.

Utilizing Sustainable Wood Sources

Among the fundamental components of sustainable manufacturing is the choice of timber from responsibly taken care of woodlands. Deciding for wood that is certified by organizations such as the Forest Stewardship Council (FSC) makes sure that the materials are sourced in an environmentally pleasant fashion. This practice not only sustains biodiversity and ecological community health but also enhances our dedication to sustainability.

Optimizing Resource Efficiency

Resource effectiveness is a cornerstone of sustainable manufacturing. By executing methods that decrease waste and maximize making use of materials, we can substantially lower our environmental impact. This involves precise planning and the use of advanced innovation to ensure that every item of wood is utilized effectively in the manufacturing process.

Energy-Efficient Manufacturing Processes

Embracing energy-efficient production processes is anotherl essential element of sustainable production. This consists of utilizing equipment and tools that take in less power and including renewable resource resources in any place feasible. By minimizing power consumption, we add to a reduced carbon footprint and promote an extra-lasting sector.

Recycling and Waste Management

Effective recycling and waste administration strategies are important in preserving sustainability in wood door production. By reusing wood scraps and results, we can minimize the amount of waste sent to garbage dumps and take advantage of products that would certainly otherwise be discarded. Executing an extensive waste administration plan aids in conserving sources and decreasing environmental impact.

| Sustainable Practice | Benefits |

|---|---|

| Utilizing Sustainable Wood Sources | Sustains biodiversity, makes certainly accountable sourcing |

| Enhancing Resource Efficiency | Lowers waste, makes best use of product usage |

| Energy-Efficient Manufacturing | Reduces energy intake, lowers carbon impact |

| Recycling and Waste Management | Reduces waste, preserves resources |

Involving in Continuous Improvement

Lastly, sustainable manufacturing is a recurring process that requires continual enhancement. By on a regular basis analyzing our production approaches and looking for ingenious solutions, we can enhance our sustainability efforts. Engaging with sector developments and embracing brand-new technologies allows us to continue to be at the centre of sustainable contemporary wood door manufacturing.

Educating Skilled Craftsmanship for Quality Assurance

In the realm of modern wood door production, the role of proficient workmanship can not be overstated. It is important to educate craftsmen who are not only adept in traditional woodworking methods but also acquainted with the most recent technical improvements in the industry. This training ensures that every wood door created meets the greatest standards of high quality.

Value of Skilled Craftsmanship

Skilled artisans are the backbone of top quality assurance in timber door production. Their proficiency guarantees that each action of the manufacturing procedure, from material option to finishing, is carried out with accuracy. Educating programs should focus on boosting both the technical abilities and the artistic sensibilities of these craftsmen.

Comprehensive Training Programs

To maintain quality in modern wood door production, it is essential to create thorough training programs. These programs ought to cover:

| Training Component | Goal |

|---|---|

| Product Knowledge | Recognizing the residential or commercial properties and ideal uses of different timber types. |

| Advanced Tool Operation | Mastering making use of accuracy cutting and shaping devices. |

| Top Quality Control Techniques | Applying rigorous quality guarantee testing methods. |

| Completing Techniques | Using resilient and visually pleasing coatings. |

Ongoing Skill Development

Along with first training, continuous ability development is vital. This includes remaining updated with the most recent market trends and technologies. Regular workshops and seminars can supply craftsmen with the possibility to learn and adopt brand-new methods, ensuring that the quality of timber doors remains continually high.

Mentorship and Apprenticeship

Mentorship and instruction programs are indispensable in cultivating competent workmanship. Experienced craftsmen can give their expertise and skills to newcomers, promoting a culture of excellence and continual renovation in contemporary wood door production.

By buying the training and advancement of proficient artisans, manufacturers can make certain that their timber doors are not only of top quality but also satisfy the developing demands of the marketplace.

FAQs on Ensuring Quality in Modern Wood Door Production

What are the key materials used in modern wood door production?

Modern wood door production typically involves materials such as solid hardwood (oak, maple, mahogany), engineered wood, and wood veneers. Engineered cores provide stability, while veneers enhance aesthetics.

How is sustainability integrated into modern wood door production?

Sustainability is achieved through responsibly sourced wood, recycled materials, and low-VOC finishes. Manufacturers also adopt energy-efficient processes and minimize waste in production.

What advanced technologies are used in modern wood door production?

Technologies like CNC machining, laser cutting, 3D modeling, and automated finishing systems are used to ensure precision, efficiency, and high-quality outputs in modern wood door production.

What are the steps involved in modern wood door production?

The process includes material selection, cutting, assembly, sanding, finishing, and quality inspection. Advanced steps, like veneer application and custom engraving, may also be part of the production.

How are modern wood doors designed to prevent warping?

To prevent warping, kiln-dried wood is used, and layers of engineered wood or cores are integrated. Moisture-resistant coatings and construction techniques also help maintain door stability.

What customization options are available in modern wood door production?

Customers can customize wood species, panel designs, finishes, dimensions, hardware, and additional features like glass inserts or carved patterns.

What makes modern wood doors energy-efficient?

Energy efficiency is achieved with insulated cores, weather stripping, and tightly sealed designs. These features reduce heat transfer and enhance energy savings.

What types of finishes are applied in modern wood door production?

Common finishes include stains, paints, clear lacquers, and water-based sealers. These finishes protect the wood while allowing for aesthetic customization to match interior or exterior styles.

How do manufacturers ensure quality in modern wood door production?

Quality assurance involves testing for strength, durability, and weather resistance. Many manufacturers follow industry standards and conduct inspections throughout production.

What design trends influence modern wood door production?

Trends include minimalist styles, natural wood tones, mixed materials (wood and metal), and features like frosted glass inserts. Custom patterns and eco-friendly designs are also popular.

References

- Door & Door, “How wooden doors are made,” https://www.dooranddoor.com/how-wooden-doors-are-made

- ArchDaily, “From Tradition to Innovation: How Modern Technologies are Transforming the Potential of Wood,” https://www.archdaily.com/modern-wood-technologies

- Wood Magazine, “Choosing the Right Wood for Doors,” https://www.woodmagazine.com/door-materials-guide

- Custom Wooden Door Manufacturer, “Discover Innovative Technologies in Wood Door Manufacturing,” https://www.customwoodendoors.com/modern-technologies-in-wood-doors

- Fine Homebuilding, “Types of Wood and Treatments for Durable Doors,” https://www.finehomebuilding.com/door-material-treatments

- Engineering News, “Advances in Laminated Timber for Door Applications,” https://www.engineeringnews.com/laminated-timber-doors

- Popular Mechanics, “Exploring CNC in Modern Door Fabrication,” https://www.popularmechanics.com/cnc-door-manufacturing

- Building Design & Construction, “Thermal and Fire-Resistant Wood Door Technologies,” https://www.bdcnetwork.com/thermal-wood-doors

- Door Insight, “Sustainable Practices in Wood Door Manufacturing,” https://www.doorinsight.com/sustainable-wood-doors

- Architecture Ideas, “Veneer and Composite Wood Doors: Innovations,” https://www.architectureideas.com/veneered-doors

- Global Wood Technologies, “Pressure Treatment Enhancements for Modern Doors,” https://www.globalwoodtech.com/pressure-treated-doors

- Timber Journal, “AI and Robotics in Wood Door Production,” https://www.timberjournal.com/robotic-door-fabrication

- EcoBuild, “Green Alternatives in Wooden Door Design,” https://www.ecobuild.com/green-wood-doors

- Furniture Journal, “MDF vs. Solid Wood for Door Cores,” https://www.furniturejournal.com/mdf-core-doors

- Houzz Pro, “Aesthetic Trends in Modern Wooden Doors,” https://www.houzzpro.com/modern-wooden-door-trends

- Construction Times, “Prefabricated Wooden Doors: Efficiency Gains,” https://www.constructiontimes.com/prefabricated-wooden-doors